United Thermal and Sound Insulation Prefabricated Walls

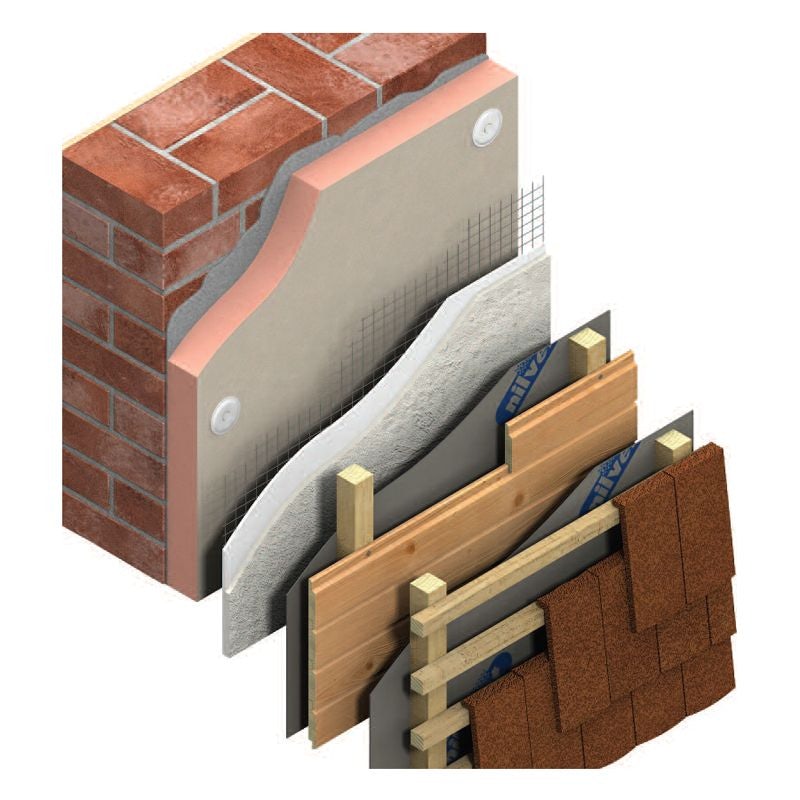

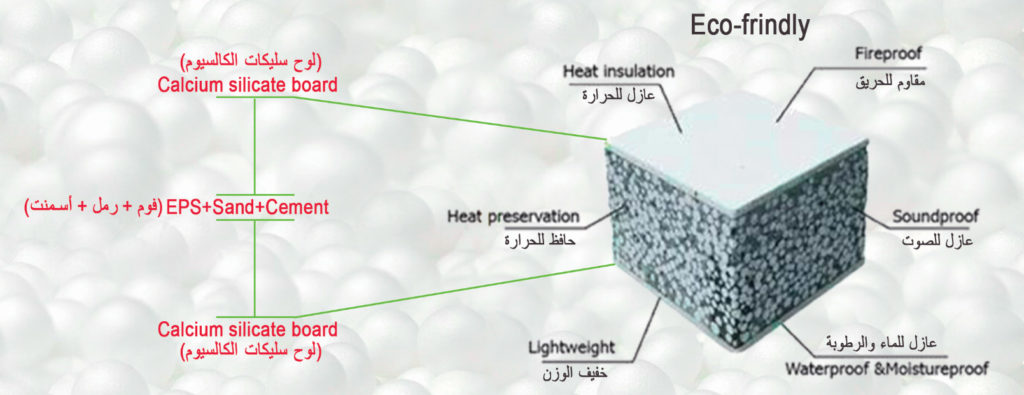

Precast concrete wall panels are made of base materials (EPS, cement, sand) and calcium silicate board. Precast concrete wall panels can replace building materials such as red bricks, clay bricks, bricks, color-coated sandwich panels blocks, perlite equivalent mesh panels, porous perlite board etc. It can be widely applied to various low building such as: bank building, office, hospital, school, hotel, shopping mall, entertainment halls, mobile housing, old house reconstruction, family house and work shop.

Data for United Thermal and Sound Insulation Prefabricate walls:

Product Name | United Thermal and sound insolation Prefabricated Walls. |

Width | 610 mm. |

Thickness | 60/75/90/100/120/150/200 mm |

Height | 2270/2440/2800 mm |

Color | White or Cementitious |

Application | Internal partition, external wall in modern tall buildings, factories, hotels, schools and every type of houses and buildings. |

Application of United Thermal and Sound Insulation Prefabricated Walls:

Precast lightweight concrete walls can be used widely in industry and civil buildings like schools, banks, offices, hospitals, hotels, workshops, houses, factories, mobile buildings, entertainment halls, booths, basements, etc..

United Thermal and Sound insulation Prefabricated Walls:

- Saves green energy (Environmentally friendly) : Materials used in precast walls don't include toxic material, and it largely improves energy saving in buildings, government strong recommends it.

- Long life (like concrete) : Building life rated at 70+ years.

- Strong : trong surface able to handle up to 50 KG hanging weight at one spot using one nail.

We Guarantee

-

The EPS (Expanded polystyrene) is avoid of nutritional value, which could support the growth of bacteria, fungi and other microorganisms.

-

The EPS is non-toxic.

-

Resistance to humidity: EPS is impermeable to water.

-

EPS is self-extinguishing.

-

EPS can work with mortars and plasters.